There is a lot that goes into maintaining a railway and keeping operations safe. The Maidstone Miniature Railway operates under the Amusement Devices Act and the Society, through MEANZ, maintains our Standard Operating Procedures which cover the safe operation of the railway.

Before an operating day the track needs to be inspected to make sure there is no damage. As the railway is within a public park we occasionally have vandalism issues or lawn mower strikes that need to be fixed.

Rail vehicles are required to undergo a yearly inspection to ensure that there is no wear and tear that may cause a safety issue. These inspections are recorded by members and we have a biannual audit of the railway to ensure things are being maintained in a safe manner.

Just like the real railway the Maidstone miniature railway is susceptible to weather events. Clearing of culverts ensures drainage is maintained to clear most rain however blocked culverts still happen which results in flooding of the railway. Most of the time this causes minimal damage to the railway other than debris on the tracks that needs to be cleared to enable trains to operate and to prevent moisture being held against the rails.

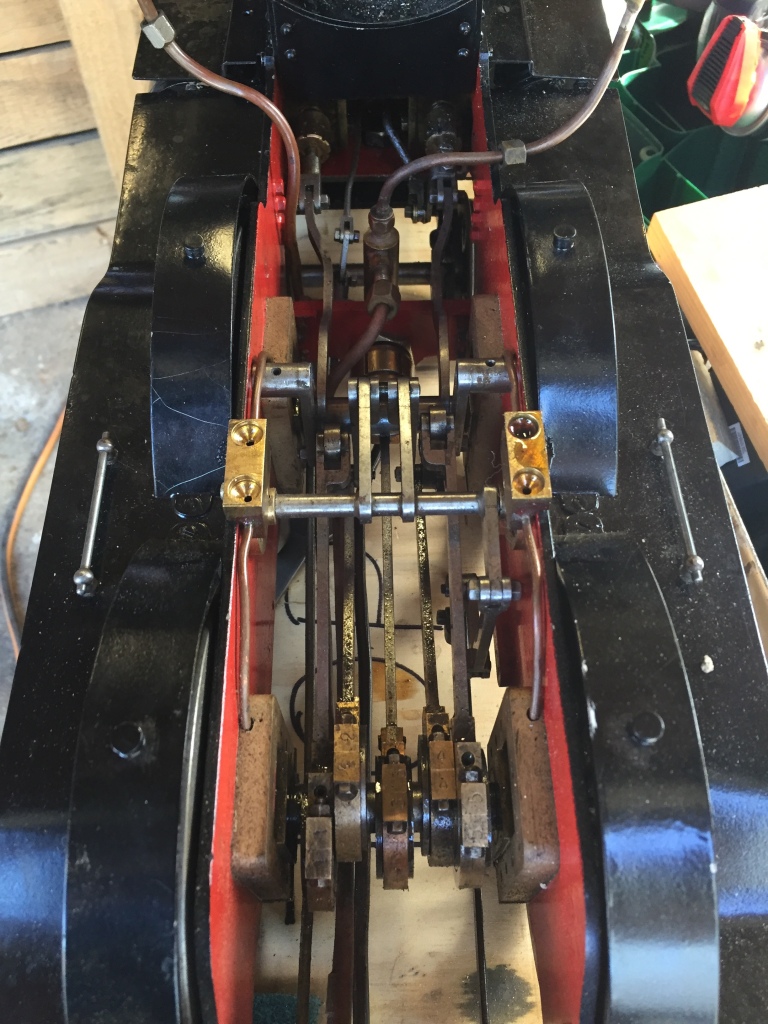

When members aren’t at the railway they are maintaining or building new equipment to operate. Here we the locomotives boiler removed we can see the internal valve gear. A large part of the enjoyment of the hobby is in the building and maintenance of locomotives to operate on the railway.